Diecasting has emerged as a significant manufacturing process in Malaysia, contributing to the country’s industrial growth and economic development. This precision casting method involves forcing molten metal into a mold cavity under high pressure, resulting in highly accurate and complex metal parts. Malaysia’s diecasting industry has evolved over the years, driven by advancements in technology, increasing demand from various sectors, and strategic government initiatives. Today, diecasting plays a crucial role in the Malaysian manufacturing landscape, supporting industries such as automotive, electronics, and consumer goods.

The history of diecasting in Malaysia dates back to the mid-20th century when the country began to industrialize. Initially, diecasting was primarily used for producing simple metal parts for domestic use. However, as Malaysia’s economy grew and diversified, the demand for more complex and high-precision components increased. This shift was fueled by the expansion of the automotive and electronics industries, which required high-quality diecast parts for their products. The Malaysian government recognized the potential of diecasting to drive industrial growth and implemented policies to support its development, including investment in technology and infrastructure.

Technological advancements have been a key driver of the diecasting industry’s growth in Malaysia. The adoption of computer-aided design (CAD) and computer-aided manufacturing (CAM) has revolutionized the production process, allowing for greater precision and efficiency. Modern diecasting techniques, such as vacuum die casting and squeeze casting, have also enhanced the quality and durability of diecast parts. Additionally, advancements in materials science have led to the development of new alloys with superior properties, expanding the range of applications for diecast components. These technological innovations have enabled Malaysian diecasters to compete on a global scale, meeting the stringent quality standards of international markets.

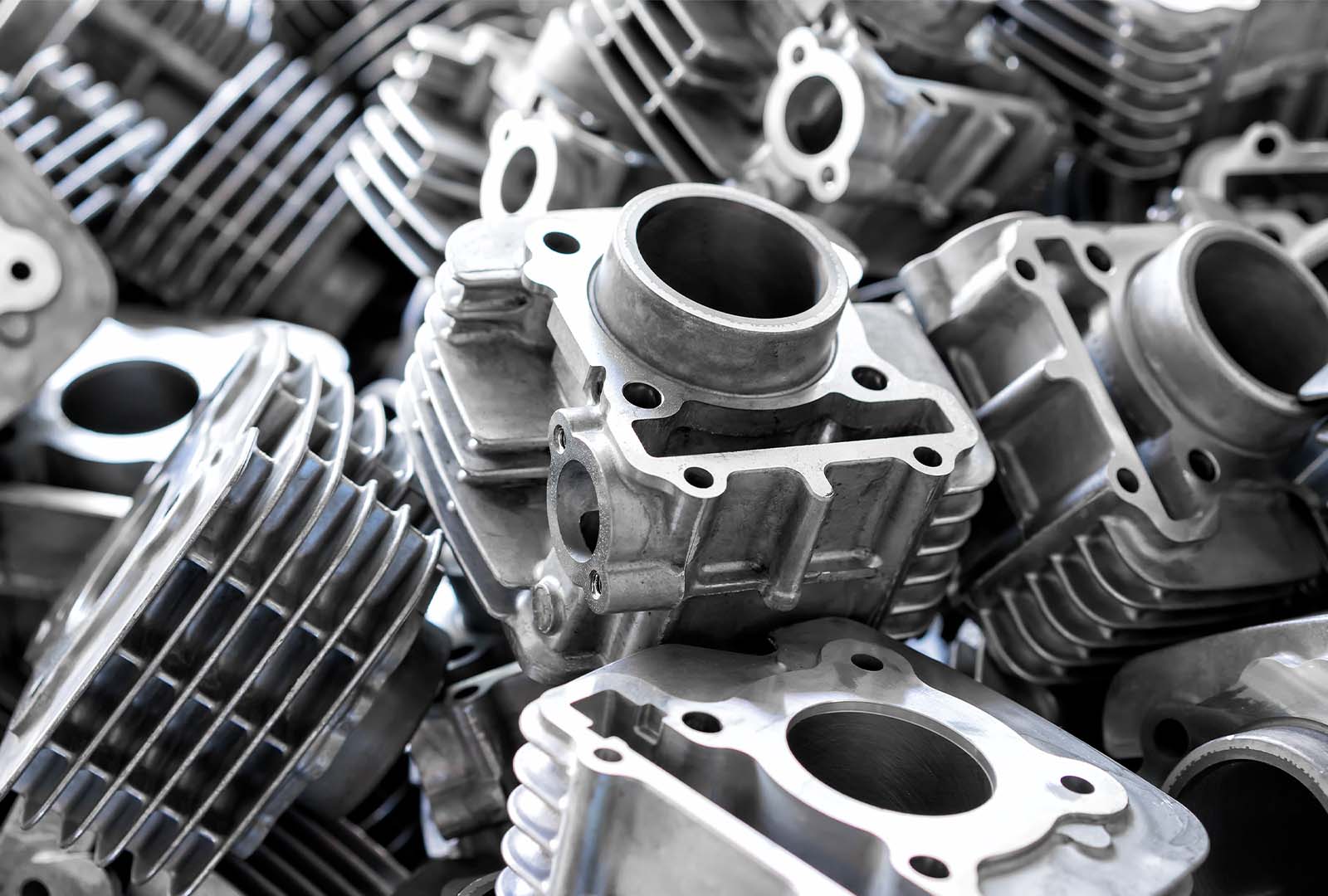

The automotive industry is one of the primary beneficiaries of Malaysia’s diecasting capabilities. Diecast components are essential for manufacturing various parts of a vehicle, including engine blocks, transmission cases, and structural components. The precision and durability of diecast parts make them ideal for automotive applications, where performance and reliability are critical. Malaysia’s strategic location and well-developed infrastructure have attracted numerous automotive manufacturers, further boosting the demand for diecast components. The diecasting industry’s ability to meet this demand has positioned Malaysia as a key player in the global automotive supply chain.

In addition to the automotive sector, the electronics industry also relies heavily on diecast components. Diecasting is used to produce intricate and precise parts for electronic devices, such as housings, connectors, and heat sinks. The growing consumer electronics market, driven by increasing demand for smartphones, laptops, and other devices, has created significant opportunities for Malaysian diecasters. By leveraging advanced manufacturing techniques and maintaining high-quality standards, Malaysia has established itself as a reliable supplier of diecast components for the electronics industry. This success has contributed to the country’s reputation as a hub for high-tech manufacturing.

Looking ahead, the future of diecasting malaysia appears promising. The ongoing trend towards lightweight and fuel-efficient vehicles is expected to drive demand for diecast aluminum components in the automotive industry. Similarly, the rapid growth of the electronics sector will continue to create opportunities for diecasters. To capitalize on these trends, Malaysian diecasters must continue to invest in technology and innovation, focusing on improving efficiency and sustainability. The government can also play a vital role by providing support for research and development and fostering a conducive business environment. By embracing these opportunities, Malaysia can strengthen its position as a leader in the global diecasting industry.

In conclusion, diecasting has become a vital part of Malaysia’s manufacturing sector, supporting key industries such as automotive and electronics. The evolution of the diecasting industry, driven by technological advancements and strategic initiatives, has enabled Malaysia to compete on a global scale. As the demand for high-quality diecast components continues to grow, the future of diecasting in Malaysia looks bright. By investing in innovation and maintaining high standards, Malaysian diecasters can seize new opportunities and contribute to the country’s economic development. The journey of diecasting in Malaysia is a testament to the nation’s commitment to industrial growth and technological progress.