Magnetic Belt Conveyor have actually reinvented product taking care of in markets that need the transport of metal products. The principle responsible for these conveyors is easy yet strongly helpful: they use magnetic pressures to move iron products along a belt. This style of conveyor unit has shown to be actually an crucial answer in markets including reprocessing, mining, production, and meals processing, where reliable, safe, and specific transportation of materials is actually essential. Unlike typical bearers, magnetic district bearers utilize magnetics embedded in the belt to attract and keep metallic products, lessening the danger of products sliding or even obtaining shed throughout transportation. This special component enhances their capacity to relocate metal things flawlessly through facility assembly-line production, resulting in better effectiveness in various commercial functions.

Among the major perks of magnetic belt conveyors is their capacity to carry iron materials that would be actually challenging to relocate along with frequent bearers. The magnets installed within the bearer district draw in as well as keep metal items, ensuring they stay in area as they relocate along the conveyor. This is actually specifically valuable in reusing plants where steel fragment, such as light weight aluminum, steel, and iron, needs to be separated and relocated to different portion of the center. In creating environments, Magnetic Belt Conveyor can easily additionally move tiny steel components, bolts, as well as devices without the need for hands-on dealing with. By delivering exact control over the activity of metallic materials, magnetic belt bearers decrease the possibilities of component loss and also streamline the transport procedure, producing it less complicated to arrange and also relocate components as demanded.

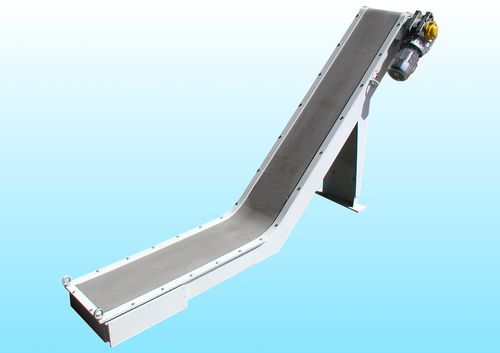

The adaptability of magnetic district bearers enables them to be adjusted for a variety of requests, consisting of those in atmospheres with high-speed assembly-line production or regions where area is actually limited. These conveyors are available in different setups, including level or prone districts, as well as may be designed to relocate components in both horizontal and also upright paths. They could be customized along with different forms of magnetics, ranging from permanent magnets to electromagnets, depending upon the material handling needs of the facility. For instance, electromagnets may be activated and also off, supplying the flexibility to take care of various component kinds relying on the situation. The capability to customize the magnetic force makes sure that the unit is suitable for moving objects of varying dimensions as well as weights, producing Magnetic Belt Conveyor suitable for a large range of sectors.

An additional crucial benefit of magnetbandförderer is their ability to increase performance as well as reduce operational down time. Conventional conveyors that rely upon rubbing to relocate products can experience recurring concerns including slipping, blocking, or requiring upkeep because of the damage on districts. Magnetic bearers, nonetheless, make use of the magnetic destination to hold metal things in location, considerably lowering the odds of product loss or hold-ups in the transport method. This effectiveness equates right into less time invested repairing or ceasing the assembly-line production for repairs. Industries that depend on high-speed assembly-line production, including meals processing or even electronic devices creating, can easily help significantly coming from the continuous, hassle-free operation that magnetic belt bearers give. Through minimizing the risk of disruptions, these conveyors assist to preserve constant productivity levels, leading to far fewer hold-ups and also much higher output.

Yet another perk of Magnetic Belt Conveyor is their resilience as well as low servicing needs. Typical bearers can easily experience notable damage due to friction in between the belt and also the components being actually transported. This rubbing usually causes belt degeneration, mechanical breakdowns, as well as the demand for frequent maintenance. Magnetic Belt Conveyor, having said that, adventure much less rubbing considering that the magnetic pressure keeps the products in place without the necessity for physical contact. Because of this, the waistbands tend to last longer as well as experience far fewer concerns, lessening the need for steady repair work as well as substitutes. In fields that handle massive or even rough materials, Magnetic Belt Conveyor supply a additional reputable and also cost-efficient answer for component transportation. Moreover, their low servicing attributes makes all of them easier for services, as they demand far fewer information to always keep the system managing efficiently.

Aside from their effectiveness and low servicing, Magnetic Belt Conveyor offer safety and security benefits that are actually crucial in numerous commercial settings. When managing hefty or even harmful materials, such as sharp steel parts or scrap steel, employees are actually at danger of injury coming from taking care of these components personally. By automating the transportation of ferrous products, magnetic bearers decrease the need for employees to actually deal with risky things, reducing the risk of reduces, tensions, and incidents. Furthermore, the magnetic intensity holds materials tightly in location, lessening the danger of things diminishing the bearer and also triggering damages to the creation line or positioning a safety risk. In settings like reprocessing facilities or even junk yards, where steel items may be large, stinging, and also complicated to relocate, magnetic bearers enrich worker security through maintaining products included and also making certain that they move safely via the system.